The compressor utilizes an imported, fully enclosed scroll compressor. Its mechanism is simple and maintenance-friendly, consisting of two scrolls—one fixed and the other rotating. During compression, refrigerant pressure continuously rises, and high-pressure, high-temperature refrigerant gas is discharged from the center of the scroll. Under equivalent horsepower conditions, its compression efficiency is over 10% higher than that of a reciprocating compressor.

This series of air conditioners uses the environmentally friendly refrigerant R-410A. This refrigerant is a 50/50 mixture of R-32 and R-125, exhibiting azeotropic properties and ease of maintenance. R-410A has an ozone depletion potential (ODP) of 0, making it non-ozone-depleting and environmentally friendly.

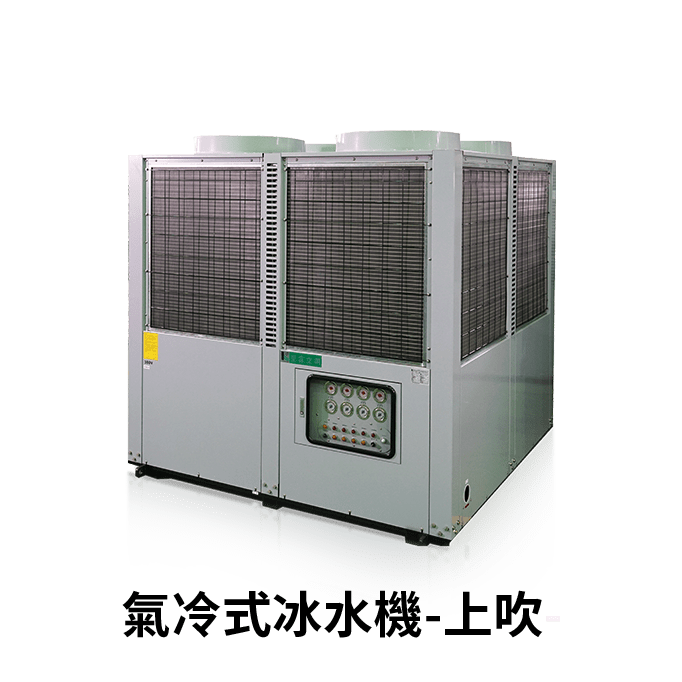

Air-cooled chillers utilize a tube-fin heat exchanger structure, cooling the high-temperature refrigerant with air. This eliminates the need for cooling water pumps, cooling towers, or cooling water pipes in the surrounding system, resulting in low and easy annual maintenance costs for the air conditioning system. Furthermore, they do not generate Legionella bacteria, which poses no environmental risk to the building environment or personnel.

Our air-cooled main unit uses a five-blade integrated molded plastic-steel fan blade, which has the characteristics of large air volume, low noise, salt damage resistance and durability.

This series of models all use imported R-410A special external pressure-equalizing thermal expansion valves to ensure that the gas refrigerant returning to the compressor is in an overheated state, avoiding liquid compression that may cause damage to the compressor, and ensuring high reliability of the host operation.