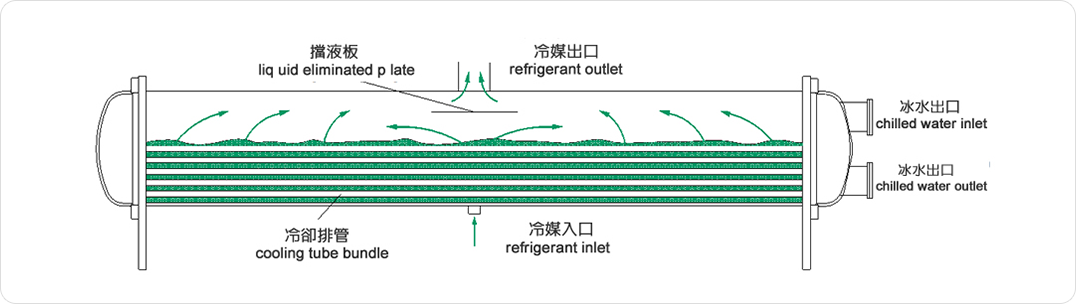

The flooded evaporator uses the principle of boiling heat transfer to completely immerse the cooling tubes in the liquid refrigerant on the shell side. Through the heat exchange process, the heat from the ice water flowing through the tubes is removed to achieve the purpose of cooling.

During the heat exchange process, the refrigerant in the shell side is in a boiling state, and the heat transfer efficiency is greatly improved. The heat transfer coefficient can be more than three times that of the evaporation heat transfer in a traditional direct expansion evaporator.

Direct expansion systems, limited by the temperature-sensing expansion valve, must maintain a superheat of 5-8°C at the evaporator outlet. This results in a dry zone covering 15-20% of the total cooling tube area. The superheated refrigerant vapor in this zone provides only a small cooling enthalpy difference, inhibiting the evaporation temperature from rising. Flooded evaporators eliminate this superheat restriction, completely immersing the cooling tubes in liquid refrigerant, allowing the refrigerant to fully utilize the cooling enthalpy difference. This raises the evaporation temperature by 2-3°C, significantly improving evaporator capacity. In flooded evaporators, chilled water flows through the tubes, creating a turbulent flow and improving the water-side heat transfer coefficient by 2-3 times compared to direct expansion evaporators. The chilled water, operating on the tube side, facilitates scale removal.